Printing is now free for all Penn students — 3-D printing, that is.

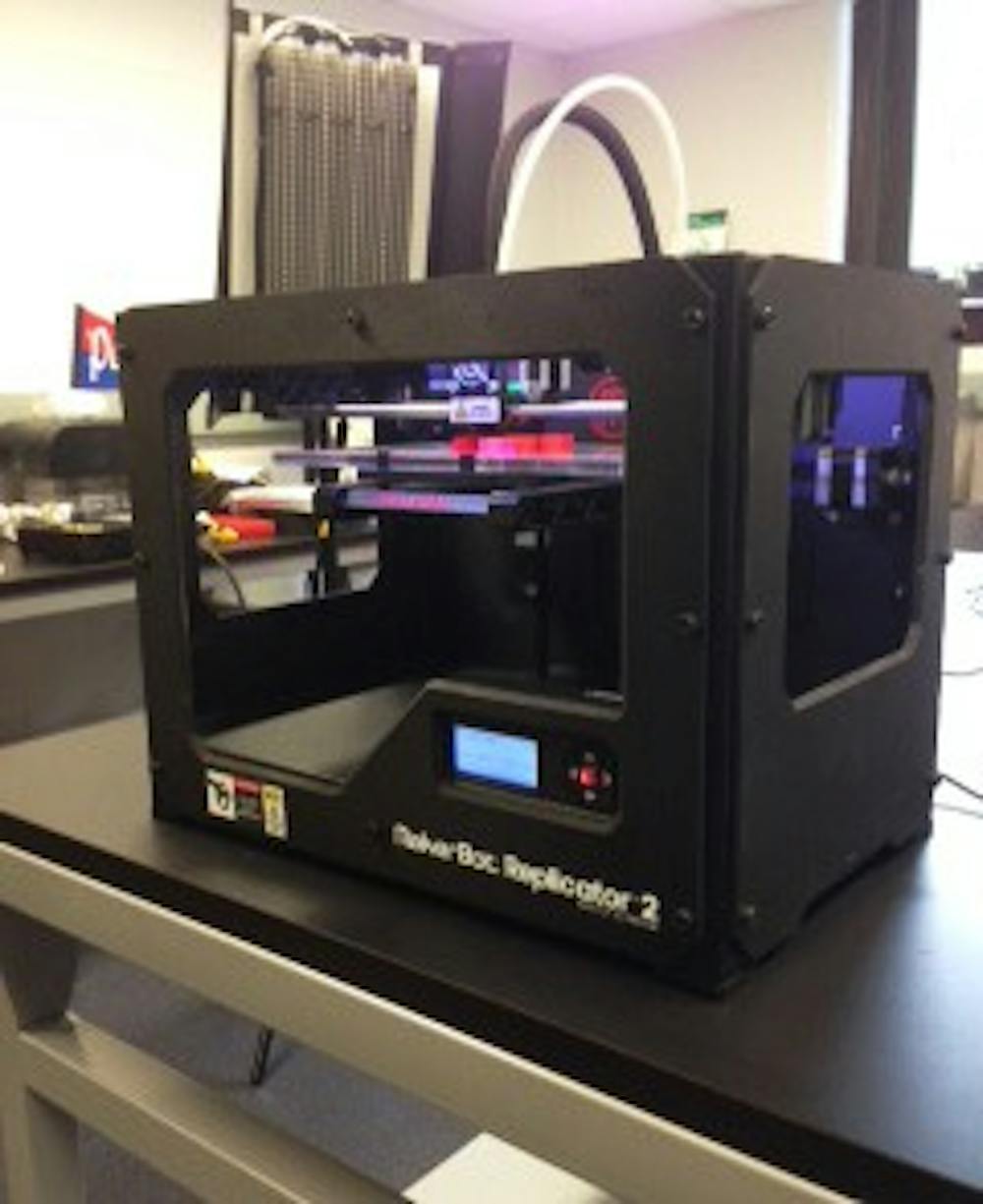

Four 3-D printers will be available for use in the Addlab , “an in-house service bureau for the Penn community” housed in the Engineering School’s Towne Building that opens its doors on Oct. 2. The “Add” in Addlab stands for additive manufacturing, an alternate name for 3-D printing.

“We are here to help people realize their designs and help them create,” said Nick Parrotta ,Coordinator of Instructional Laboratories at Penn .

The lab came to fruition, in part, due to an anonymous $250,000 donation. Members of the Penn community can print academic projects for free using one of the four printers , while the other three printers will cost between $18 and $22 per cubic inch, not including the cost of material .

Katherine Kuchenbecker , an associate professor in the Mechanical Engineering and Applied Mechanics and Computer and Information Science departments , already uses 3-D printing in her research and believes the lab will add value to Penn’s scientific research.

In her lab, Kuchenbecker works on giving robots a sense of touch, specifically to enhance minimally invasive robotic surgery. Kuchenbecker used the quick, inexpensive method of 3-D printing to create the prototype for the sensor attachments.

“The technology has some short-comings,” Kuchenbecker said. “One of them is that the surgeon doesn’t have any tactile feedback — they cannot feel what the instruments [are] touching inside of the patient. We invented a way to add touch feedback, but it required adding touch sensors to the robot.”

Printing only takes a couple of hours, Kuchenbecker explained, and using the printers does not require in-depth training. Compared to other methods for creating prototypes, 3-D printing is also relatively inexpensive.

3-D printing works through computer-aided design, where computer programs enable a machine to essentially hot-glue plastic into any geometric 3-D shape. 3-D printers can work with many different materials, including metal and silicone, but the printers at the Addlab work mostly with plastic .

The engineering complex has several 3-D printers scattered throughout, but the Addlab has “a comprehensive suite of instruments along with a trained staff who can assist in the design process,” Carpick added. Academics from the Hospital of the University of Pennsylvania and the Children’s Hospital of Philadelphia may also use the lab.

Robert Carpick , a professor in the Mechanical Engineering and Applied Science Department , studies the properties of friction. In one of his projects, he needed to create a specific device that could measure friction inside of a complex instrument.

“Being able to 3-D print a plastic version of the part I need enables me to make sure that it fits correctly,” Carpick said. “We can double check that the parts work together as we move it around.” The lab, he added, brings Penn’s mechanical engineering department to the forefront of the field.

Carpick will be giving a complete tour of the lab and a demonstration on 3-D printing objects today at 4 p.m. in the Towne Building .

The Daily Pennsylvanian is an independent, student-run newspaper. Please consider making a donation to support the coverage that shapes the University. Your generosity ensures a future of strong journalism at Penn.

DonatePlease note All comments are eligible for publication in The Daily Pennsylvanian.